Igama lesiNgisi lebhethri le-lead-asidi elilawulwa yi-valve yibhethri eliholayo elilawulwa yi-Valve (ibhethri le-VRLA ngamafuphi).Kukhona i-valve yokukhipha enye indlela (ebizwa nangokuthi i-valve yokuphepha) kukhava.Umsebenzi wale valve uwukukhipha igesi lapho inani legesi ngaphakathi kwebhethri lidlula inani elithile (ngokuvamile elivezwa inani lomfutho womoya), okungukuthi, lapho umfutho womoya ngaphakathi kwebhethri ukhuphukela enanini elithile.I-valve yegesi izivula ngokuzenzakalelayo ukuze ikhiphe igesi, bese ivala ngokuzenzakalelayo i-valve ukuvimbela umoya ukuthi ungangeni ngaphakathi kwebhethri.

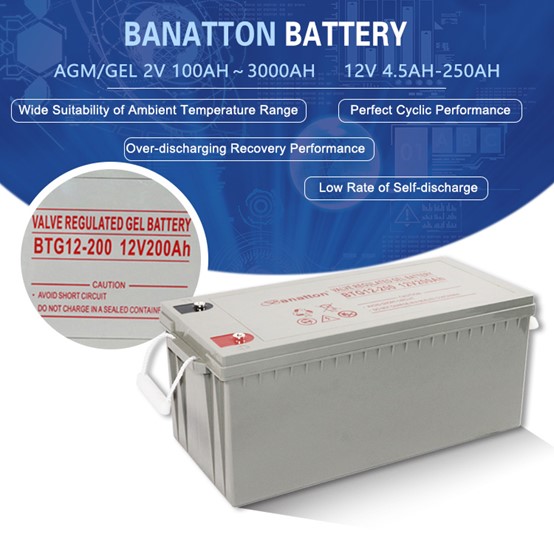

Ubunzima bokuvala amabhethri e-lead-acid yi-electrolysis yamanzi ngesikhathi sokushaja.Lapho ukushaja kufinyelela ku-voltage ethile (ngokuvamile engaphezu kuka-2.30V/cell), kukhishwa umoya-mpilo ku-electrode ephozithivu yebhethri, bese i-hydrogen ikhishwa ku-electrode eyinegethivu.Ngakolunye uhlangothi, igesi ekhululiwe ikhipha inkungu eneasidi ukuze ingcolise imvelo;Ibhethri le-lead-asidi elilawulwa yivalvu liwumkhiqizo othuthukiswe ukuze unqobe lezi zinkinga.Izici zayo zomkhiqizo yilezi:

(1) Ingxubevange yegridi yekhwalithi ephezulu ye-Multi-element isetshenziselwa ukuthuthukisa amandla angaphezu kwamandla okukhululwa kwegesi.Okusho ukuthi, ingxubevange yegridi yebhethri evamile ikhipha igesi uma ingaphezulu kuka-2.30V/cell (25°C).Ngemva kokusebenzisa ama-alloys ezingxenye eziningi zekhwalithi ephezulu, igesi ikhishwa lapho izinga lokushisa lingaphezu kuka-2.35V/monomer (25°C), okunciphisa ngokuqhathaniswa inani legesi elikhishwe.

(2) Vumela i-electrode engalungile ibe nomthamo oweqile, okungukuthi, umthamo ongaphezu kuka-10% kune-electrode eqondile.Esigabeni sakamuva sokushaja, umoya-mpilo okhishwa i-electrode ephozithivu uthinta i-electrode engalungile, iphendule, futhi ikhiqize kabusha amanzi, okungukuthi, O2+2Pb→2PbO+2H2SO4→H2O+2PbSO4, ukuze i-electrode eyinegethivu ibe sesimweni sokushajwa. ngenxa yesenzo somoya-mpilo, ngakho-ke ayikho i-hydrogen ekhiqizwayo.I-oksijini ye-electrode eqondile idonswa ukuhola kwe-electrode engalungile, bese ibuye iguqulelwe emanzini, okubizwa ngokuthi i-cathode absorption.

(3) Ukuze kuvunyelwe umoya-mpilo okhishwe i-electrode ephozithivu ukuthi ugeleze ku-electrode eyinegethivu ngokushesha ngangokunokwenzeka, uhlobo olusha lwesihlukanisi sefayibha yengilazi ecwebe kakhulu ehlukile kusihlukanisi serabha esine-microporous esisetshenziswa kumabhethri ajwayelekile aneasidi yomthofu. kumele isetshenziswe.I-porosity yayo ikhuphuka isuka ku-50% yesihlukanisi senjoloba ibe ngaphezu kuka-90%, ukuze umoya-mpilo ugeleze kalula ku-electrode ongemuhle bese uguqulwa ube amanzi.Ngaphezu kwalokho, isihlukanisi se-fiber yengilazi ecwebezelayo sinomsebenzi wokukhangisa i-electrolyte ye-sulfuric acid, ngakho-ke noma ibhethri liwiswa phansi, i-electrolyte ngeke igcwale.

(4) Isakhiwo sesihlungi se-asidi esivaliwe esilawulwa yi-valve siyamukelwa, ukuze inkungu ye-asidi ingakwazi ukuphunyuka, ukuze kufezwe injongo yokuphepha nokuvikelwa kwemvelo.

Enqubweni yokumuncwa kwe-cathode eshiwo ngenhla, njengoba amanzi akhiqiziwe engakwazi ukuchichima ngaphansi kwesimo sokuvaleka, ibhethri le-asidi elilawulwa yi-valve lingakhishwa ekunakekeleni amanzi okungeziwe, okuphinde kube umsuka womthofu ovaliwe olawulwa yi-valve. -ibhethri le-asidi elibizwa ngebhethri elingena-dimension.Nokho, incazelo yokungakhathalelwa akusho ukuthi akukho sondlo okwenziwayo.Ngokuphambene nalokho, ukuze kuthuthukiswe impilo yesevisi yamabhethri e-VRLA, kunemisebenzi eminingi yokulungisa esilindele ukuthi siyenze.Indlela yokusetshenziswa efanele ingahlolwa kuphela phakathi nenqubo.Phuma.

Ukusebenza kukagesi kwamabhethri e-lead-acid kukalwa ngalezi zimiso ezilandelayo: amandla ebhethri e-electromotive, i-voltage yesekethe evulekile, i-voltage yokunqamula, i-voltage esebenzayo, amandla okuphuma, umthamo, ukumelana kwangaphakathi kwebhethri, ukusebenza kwesitoreji, impilo yesevisi (impilo yokuntanta, ukushaja nokukhipha impilo yomjikelezo), njll.

Isikhathi sokuthumela: Apr-26-2022